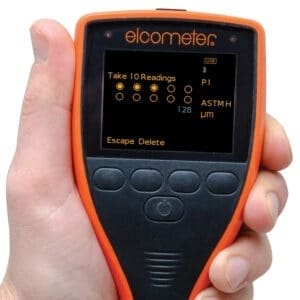

Elcometer 266 – DC Holiday Detector D266—-4C

$2,081.48 – $3,012.08

The Elcometer 266 holiday detector can be used to test porosity on coatings up to 7.5mm (300 mils) thick and is ideal for inspecting coatings on pipelines and other protective coatings. This holiday tester features a built-in voltage calculator which will determine and set the correct test voltage based upon the test standard and the thickness of coating being tested.

Elcometer 266 DC Holiday Detector Features

- Voltage calculator automatically sets the correct voltage from your coating thickness value

- Adjustable Voltage:

- 0.5kV – 1kV in 50V steps

- 1kV to 30kV in 100V steps

- Dual safety switch on handle to avoid accidental switch on (Grey/orange probe handles only)

- Internal Voltmeter/ Jeep tester ensures that the test voltage equals the selected voltage

- Visual and audible alarms, Bright LEDs on the handle, as well as a loud buzzer, clearly indicate when a holiday is detected

- To change maximum voltage range, select a different handle; 5kV, 15kV or 30kV DC or 30kV DC continuous

- A wide range of probe brushes and rolling springs available

PACKING LIST

- Elcometer 266 DC Holiday Detector

- Battery pack

- Curly connection cable for high voltage handle,

- 10m (32’) signal return lead, battery charger

- Band brush

- Shoulder strap, tough plastic carry case

- Operating instructions

ELcometer Pinhole Porosity Holiday testers data sheet